R&D Designer, Lieuwe Boards BV

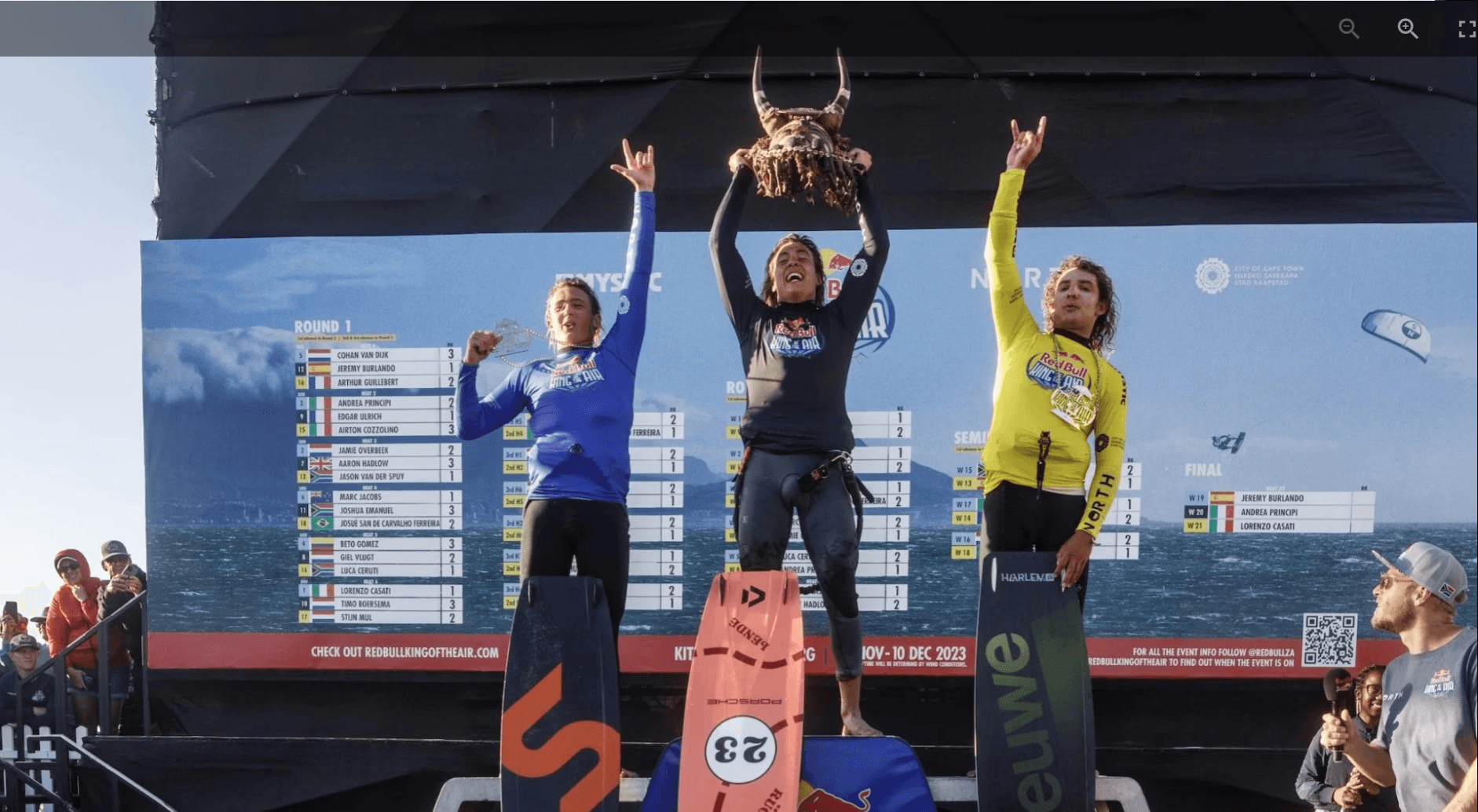

Lieuwe Boards is leading kiteboarding brand designing and manufacturing boards inhouse in the Netherlands. Together with the founder, Florian Lieuwe, I formed the R&D team at Lieuwe Boards. We were responsible for the entire design and production process. My focus was primarily on enhancing product quality, developing new models, and refining the manufacturing processes. Many boards initially did not meet quality checks, and it was my responsibility to identify, test, and implement improvements.

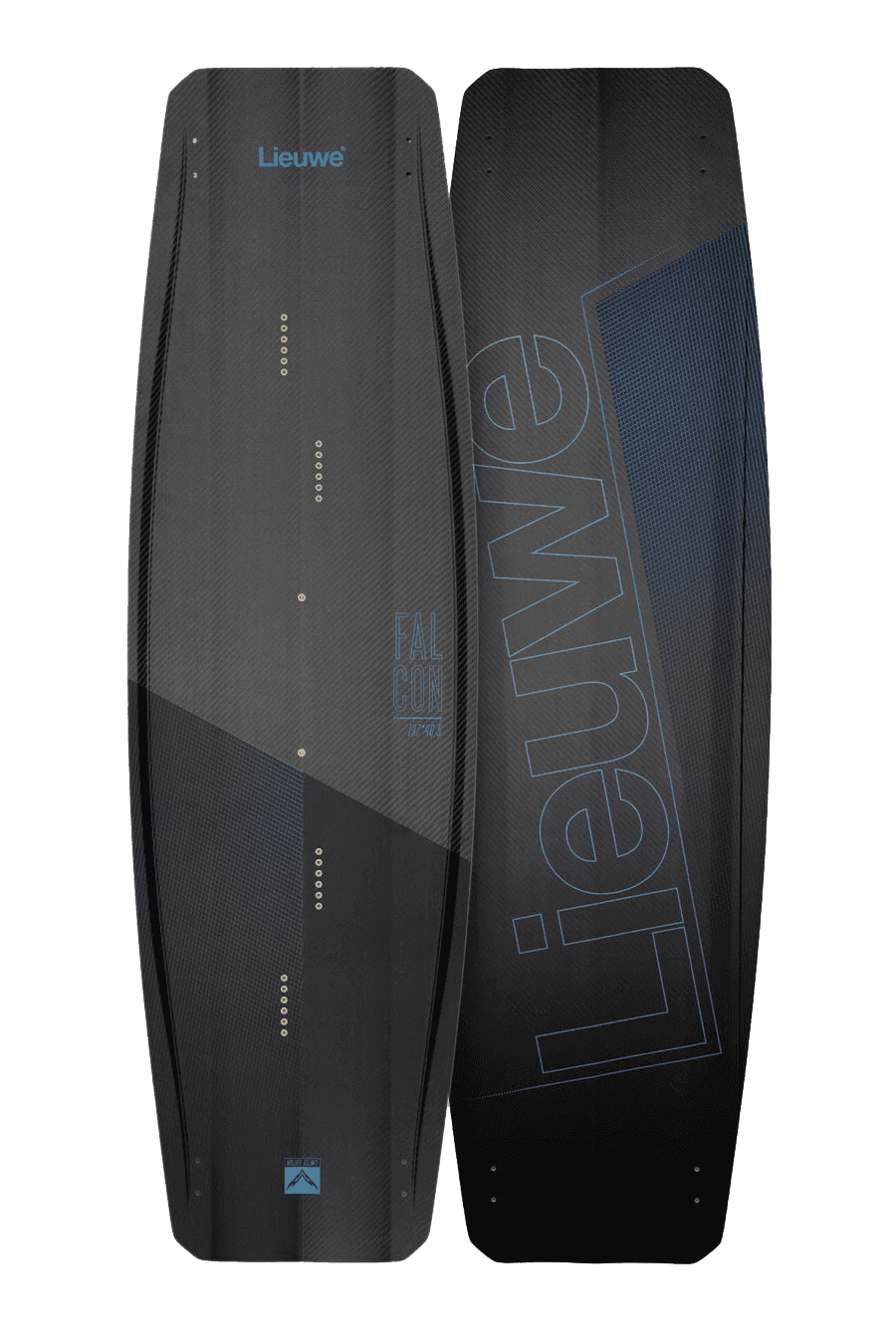

Product design

Together with Florian we developed the FALCON, Lieuwe's lightest Big Air performance kiteboard ever*. We spent a lot of time making it a comfortable Big Air booster that gives you insane levels of speed, pop and energy return, without the usual disadvantages of riding a typical stiff carbon board.

*according to the marketing team ;)

Test setups & Machine design

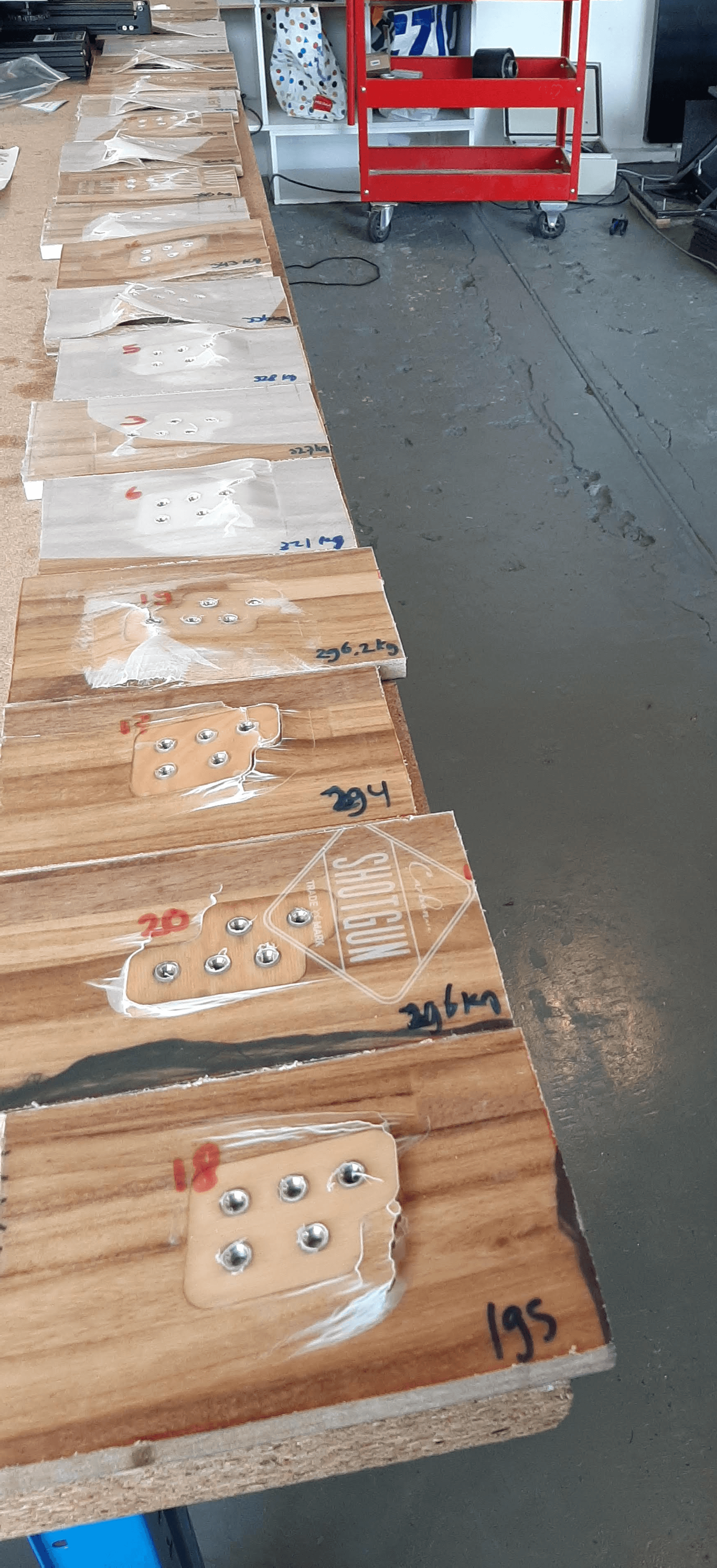

To make kiteboards lighter, more sustainable, and easier to manufacture, various components were tested, including inserts, rail composites, and biobased pre-preg layups, as wet layups were time-consuming. The deep channels on the boards required extensive adjustments to fibers, molds, and processes to avoid visible bubbles. Since the deep channels and transparent top sheet were key selling points, any imperfections were highly noticeable.

I created several low-cost test setups, including a pulling test for material strength, a UV test for sunlight resistance, and a delamination test for bonding integrity. These simple, efficient tests helped refine the boards' design and materials.

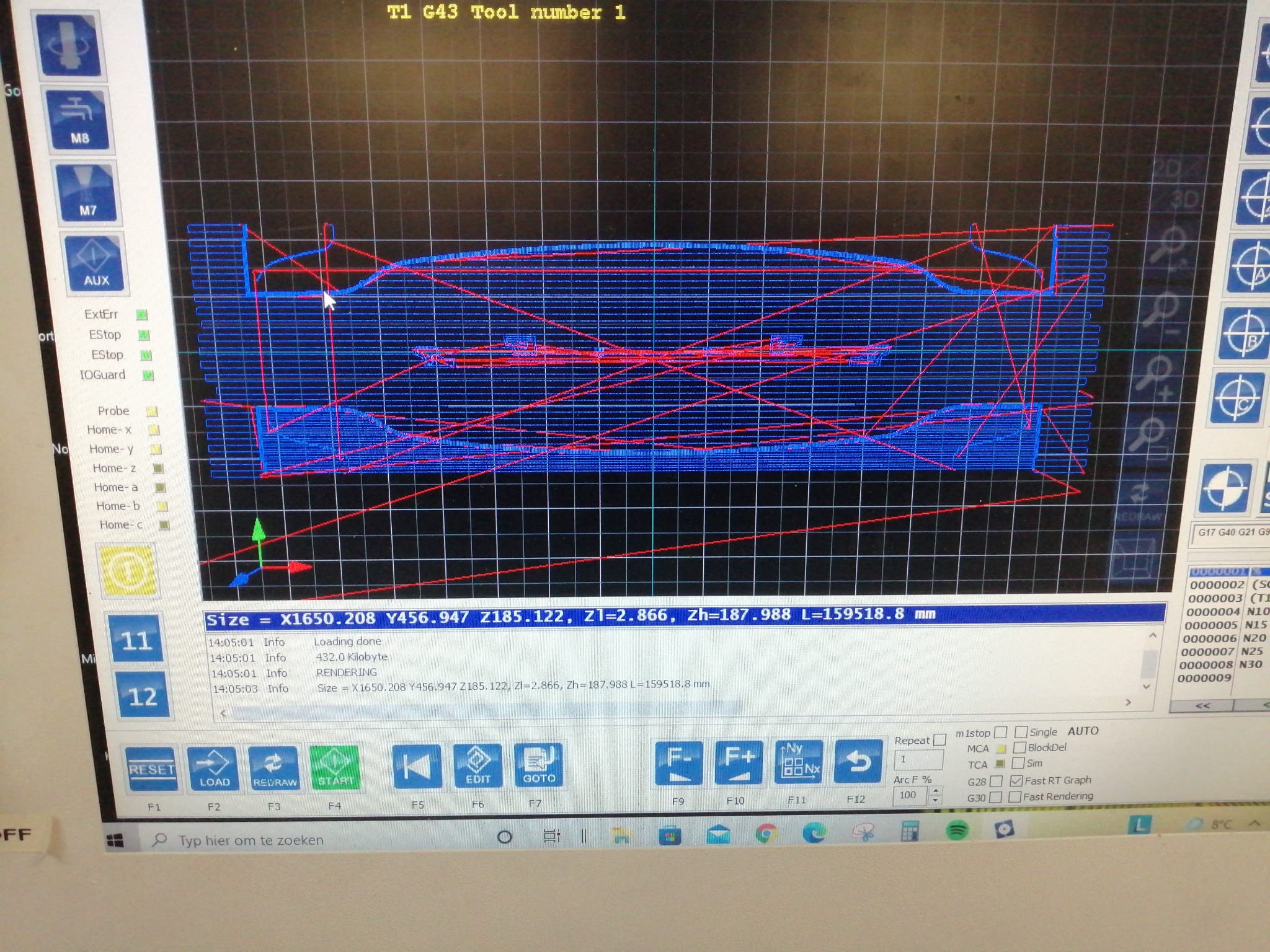

To improve reliability, safety and speed I have designed and assembled machines, transitioned to new mold materials (from HPL to aluminum(first time milling aluminium for Lieuwe), converting chaotic CAD models to parametric files, and minimizing (human) production errors using a poka-yoke approach. Over two years, we managed to significantly reduce B-quality stock and speed up the process.

Pro pads, semi-custom product

Packaging & Accessoire design

Aside from board design and manfacturing. I have participated in many smaller design projects. Such as assecoires, packaging and displaystands.

The Pro pads that are shown are semi-custom, meaning that not all components are fully developed inhouse but by the manufacturer. Desing the footbed and straps was my responsibility.

To enhance sustainability and transport safety of the boards, I designed an inlay for the board that clamped into the board’s channels for secure transit and doubled as a floor or wall stand post-delivery.

Ski development

In addition to kiteboards, I’ve always loved skiing, and once I realized the production process was so similar, I started exploring whether I could produce my own skis using their facilities. What began as a passion project in after-hours became something the team found very interesting to pursue further. I developed the entire production process including the press and created several sets of skis.